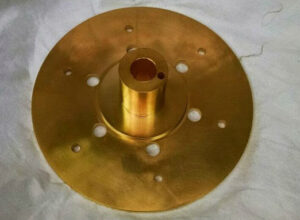

Whether you want to sell or simply keep a part that you need, you may want to consider a gold plating aluminum process. There are many options to choose from, including liquid golds, electrolytic gold plating, and soldering gold-plated parts.

Electrolytic gold plating

Whether it is for cosmetic reasons or for the protection of your electronics, electrolytic gold plating is an excellent choice. Whether you’re looking to create tooth inlays or repair damaged jewelry, gold plating is a great way to create a durable coating that is low in contact resistance and offers excellent corrosion resistance.

When it comes to re-plating your jewelry, you can take advantage of Sharretts Plating, a gold plating service in New York, for a cost-effective way to restore its luster. As with any jewelry, you can be prone to allergic reactions if you have metal allergies. By re-plating your jewelry, you’ll be able to avoid an allergic reaction for a period of time.

Besides the cost, gold plating can be an expensive process. However, when you have professionals do the job for you, you’ll be able to rest easy knowing that you’ll receive a high-quality and safe result.

A number of different metals can be used to create coatings. Some of the most common metals used for coatings include silver, gold, copper, nickel, and zinc. In addition, there are also minor metals such as ruthenium, chromium, and bi.

Although some alloys are plated on their own, gold and nickel are usually plated. This process is used to create durable coatings that are resistant to corrosion and have good electrical conductivity.

Liquid golds

Despite its relatively small cost, gold is used in construction of many electronic devices. Since gold has excellent conductivity, gold plating has become an important method of construction. Gold has been used since ancient times for decorative and monetary applications.

The oldest type of gold bath is the alkaline cyanide bath. These solutions can be semibright or matt. In the early days of gold plating, excess free alkali cyanide was used as the electrolyte. A pH range of around 3.5 to 5 is acceptable.

The cyanide-based solutions are less subject to immersion deposition and tend to convert to monovalent solutions above pH 3.0. They can also cause occasional staining problems. Nevertheless, they are used for heavy industrial coatings. They are also employed in radar equipment and high frequency conductors.

Other types of gold baths include noncyanide baths. These types are used for heavy industrial coatings and decorative coatings. They are also used in circuits and industrial solder. These baths are also sulfite-based.

For industrial applications, these solutions are often developed to ensure the uniformity of gold plating, and to reduce the extra coating. A uniform electroless Ni-P coating is also desirable, because of its good thermal properties.

New stabilized series of sulfite golds are available and can operate without brightening agents. They can also be used with cobalt.

Soldering gold-plated parts

Using a high temperature torch to melt solder is a good method for joining gold objects. However, it’s not always easy. It’s important to use a good torch that can provide the necessary heat without melting the entire object.

A good gold finish will balance corrosion and oxidation protection, as well as solderability. This finish is particularly important for miniaturization in electronics.

It’s also important to choose a good quality gold plate for your component. The best quality gold finish is one that has no contaminants or additives. Adding these can negatively affect solderability.

It’s also a good idea to use a flux to clean the surface. Flux comes in liquid or powder form. It can be mixed with water to form a paste. This helps the soldering process go smoothly.

In addition, you’ll want to use a quality underplate. A good underplate will improve the overall wear resistance of the gold plating. If the underplate isn’t strong enough, it can crack and break the hard gold contacts.

You also want to use a good-quality precision torch. It isn’t recommended to use a regular household torch to solder gold. You’ll need a high-temperature torch to ensure that the solder melts smoothly. You’ll also want to use a soldering brick to keep the heat from escaping.