Table of Contents

The process of electroplating magnesium can be complex. There are several methods to choose from, including Non-aqueous nickel, Electroless nickel, Alkyl magnesium, and Nickel/aluminum alloys. You will also learn how to protect magnesium parts with anodic coatings.

Electroless nickel

Electroless Magnesium plating is a technique for plating magnesium alloys. The process involves applying an electroless nickel alloy to a magnesium alloy substrate. The magnesium alloy surface undergoes an oxalate pretreatment prior to the application of the nickel coating.

After the electroless nickel plating process, the alloy sample is characterized by XPS and SEM. Further, the corrosion resistance of the electroless Ni-P coatings was studied through thermal sock and porosity tests.

Alkyl magnesium

The quaternary ammonium halide magnesium-alkyl magnesium electrolyte of claim 1 contains magnesium (0.5–4) and aluminum (two–8), in varying proportions. The magnesium content increases with increasing bath temperature.

In an experiment, an alloy containing 10 at. % Mg and 90 at. % Al was electrodeposited at a temperature of 100deg C. The curve was smooth and extended to about 2 at. % Mg at about 25deg C.

Non-aqueous nickel

Non-aqueous nickel and magnesium platers are an excellent choice for metal finishing. These materials are extremely durable, and they can be electroplated with any plateable metal. Whether you want a bright, high-shiny finish, or you want a low-gloss finish, these metals can meet your needs.

Alkyl magnesium/aluminum alloys

Alkyl magnesium/aluminum (MgAlAl) alloys are available in different forms. These alloys have a high specific strength and high rigidity and have moderate density. Its modulus of elasticity in tension is 44,800 MPa.

Its ultimate tensile strength is between 152 and 379 MPa. It is available as sheet and extrusions. These alloys are used for various applications in the automotive, aerospace and defense industries.

Nanocrystalline or amorphous Mg

The use of Nanocrystalline or Amorphous Mg in magnesium plating is advantageous because it can enhance the mechanical properties of Mg alloys.

This method of magnesium plating has certain advantages over traditional plating processes, such as galvanostatic and pulsed electrodeposition.

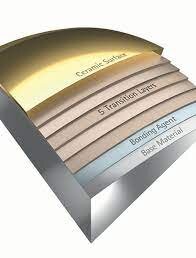

Plating on ceramics

Magnesium plating is a process to coat a magnesium alloy with a scratch-resistant ceramic coating. The process uses similar techniques to anodising. The parts are immersed in a solution containing an electrolyte and magnesium. As the metal reacts with the electrolyte, it oxidises, changing the surface structure.

The resulting layer is extremely hard and adheres well to the substrate. The process is versatile and can be used to create a variety of surface properties. In a study involving Ford engineers, the coating proved to be a highly effective corrosion protection for their vehicle parts.